Comprehensive

metalworking services, including the development of complete technology.

A 10 kW fibre-optic

laser and a Bystronic press brake with a press force of 250 tons – this is our

technological base, supported by full CAD and CAM software. Our wide range of

services, modern equipment and many years of experience in designing and

processing steel allow us to handle any order.

About us

the combination of modern technology and experience

in metalworking sets us apart

Capabilities

Learn more about our capabilities

and modern equipment,

which allows us to take on even the most demanding

orders.

Quality

production at our company is

carried out in accordance with internal standards based on 3-stage quality

control

and ISO 9001

Contact

To learn more about our

capabilities and what we can offer you, meet our specialists.

We look forward to work with you!

Tradition

Our buildings are also a

part of our heritage.

The fully restored

production buildings have been used for metal treatment since they were built

in 1885. There were once located the proudly named Royal Main Workshops in

Lubań. That fact underlines the emphasis our company places on history and

tradition. Our remembrance of the past and the prospects have allowed us to

always emphasize development and investment. As a result, today we have a broad

stock of equipment, professional staff and vast experience.

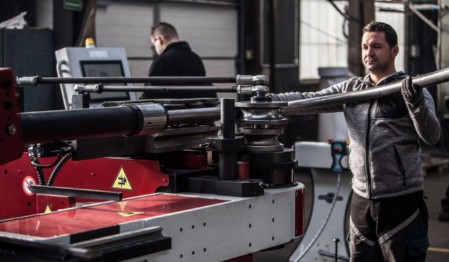

Modernity

From the Plant Manager level, we manage the entire production process,

supported by the complete By Soft 7 software. This allows us to achieve a level

of production optimization that is not otherwise available to other companies.

An equally advanced CAD/CAM system supports the tube bending machine, offering

free bending of any radius in 3D space. Our accuracy is supervised by the

Axel Systems LTD measurement system and quality is confirmed by ISO

9001 certification.